In today’s RO systems, manufacturers are increasingly turning to integrated manifolds — also called RO manifolds or integrated waterway boards — to replace the traditional tangle of tubes and fittings. This design innovation makes modern RO water purifiers simpler, cleaner, and more reliable.

Integrated Waterboard

What Is an Integrated Manifold?

In a traditional reverse osmosis (RO) system, water flows between filters through several PE tubes and quick connectors. Every joint is a potential leak point, and as RO systems evolve toward compact designs, these tubes take up valuable space.

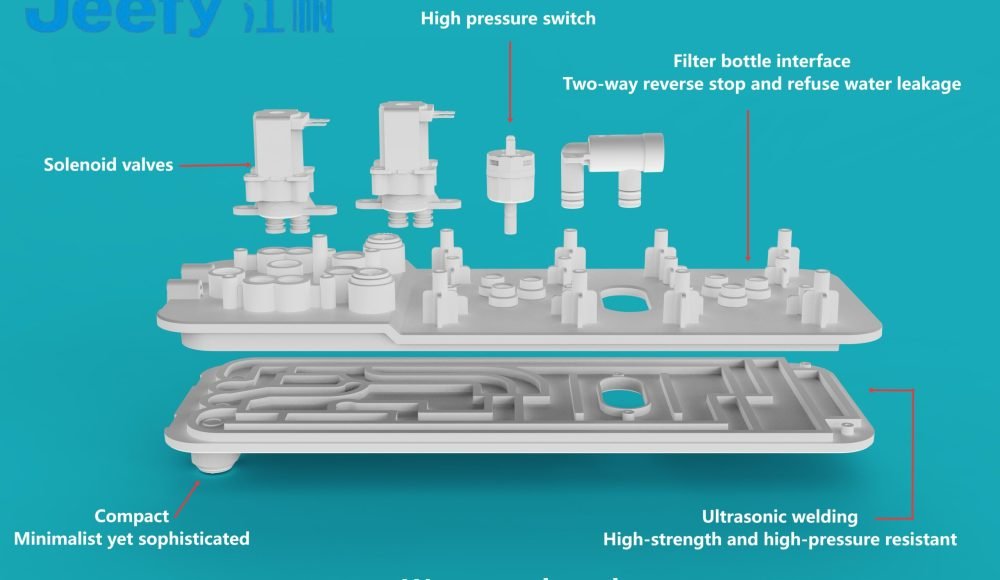

An integrated manifold solves that problem. It consolidates the internal water paths — raw water, purified water, and wastewater — into a single molded block. Instead of external tubing, the RO manifold channels water through pre-designed internal passages, providing a more compact and leak-resistant structure. Here comes its pros and cons:

Different Water Boards

Key Advantages of Using Integrated Manifolds in RO Systems

1. Leak reduction

By replacing multiple fittings with one solid integrated manifold, leak points can be reduced by up to 90%, significantly improving reliability.

2. Compact design

An RO system with an integrated manifold uses space more efficiently, enabling slimmer under-sink designs without sacrificing performance.

3. Easier production and maintenance

Fewer parts mean faster assembly during manufacturing. For technicians, maintenance is simpler because the flow paths are organized inside one clear module.

4. Consistent performance

Every RO manifold is made through precision injection molding, using food-grade materials like PP, POM, or PPO-GF. This ensures stable flow, consistent pressure resistance, and standardized quality across batches.

Considerations and Challenges

Although the integrated manifold improves overall system performance, it also requires precise mold design and a higher tooling cost. If internal channels are poorly engineered, they can restrict flow or accumulate debris over time. For this reason, only manufacturers with in-house mold development and strict quality testing can produce truly reliable RO manifolds.

Manufacturing Process and Materials

Most integrated manifolds for RO systems are produced through precision injection molding using food-grade engineering plastics such as PP (polypropylene), POM (polyoxymethylene), or PPO with glass fiber reinforcement (PPO-GF). During molding, the internal water channels are formed with micrometer-level accuracy to ensure smooth flow and consistent pressure distribution.

After molding, the upper and lower panels of the manifold are typically joined by ultrasonic welding or high-temperature fusion, creating a single sealed structure that can withstand pressure tests up to 0.7 MPa or higher. Each manifold undergoes 100 % air-tightness testing to guarantee leak-free performance before assembly into the RO system.

Water Board Air Tightness Check

Jeefy’s Experience

At Jeefy, we integrate this technology across our M-Series RO systems — including the M3, M80, M90, and M80-P models. Each manifold is injection-molded in our own facility, tested for airtightness, and optimized for our Push-n-Pull modular filter cartridges. This combination ensures clean water flow, compact design, and dependable operation throughout the product’s lifespan.

For Jeefy, the integrated manifold isn’t just a component — it’s the foundation of every reliable RO system we build.