Welcome to Jeefy’s Water Purifier Classroom. Here, we will guide you through the components inside a reverse osmosis (RO) water purifier in the simplest and most intuitive way.

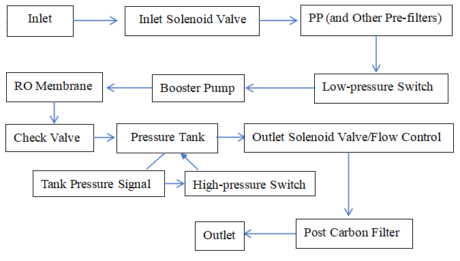

RO Water Purifier Flow Path:

Flow Path of a typical Reverse Osmosis (RO) System

- Inlet Solenoid Valve

Imagine laying the machine flat on a table and following the route starting from the tap water inlet. The first “gate” is usually the inlet solenoid valve, which works like a gatekeeper controlling when raw water can enter the system. Some models also arrange a pre-flushing process here to flush the system on startup, preventing stagnant water from remaining inside.

- Pre-filter(s)

After entering the system, the water flows through several stages of pre-filtration (commonly PP cotton, activated carbon, etc.), which mainly remove larger particles, sediment, and odors, thereby reducing the load on the finer membrane elements.

- Low-pressure Switch

The low-pressure switch is located at the inlet and acts like a “sentinel,” monitoring the tap water’s inlet pressure. If the inlet pressure is too low, the low-pressure switch will prevent the booster pump from starting to avoid damage from running dry. When the inlet pressure returns to normal, it sends a “start allowed” signal so the machine can resume water production. If the switch fails, issues like “RO pump not starting” may occur.

- Booster Pump

If it’s a reverse osmosis (RO) type purifier, the booster pump is going to be the next component, also one of the most important ones. RO membranes require sufficient pressure to work, and since household water pressure is often unstable, the pump’s job is to “boost” the pressure. The booster pump is one of the most essential reverse osmosis water purifier components, ensuring optimal pressure for the RO membrane to function properly.

- Reverse Osmosis (RO) Membrane

After the pump, water is pushed to the Reverse Osmosis Membrane, another one of the most critical components of an reverse osmosis system, where pure water and wastewater are separated. The Reverse Osmosis membrane removes dissolved salts, heavy metals, and organics, achieving a 0.0001-micron filtration precision. The wastewater will be discharged or used for flushing, depending on the model design, while the pure water flows into the next stage. To learn more about how reverse osmosis membranes remove contaminants, you can refer to this detailed explanation on Wikipedia.

- High-pressure Switch

The high-pressure switch is installed in the pure water line after the RO membrane and is responsible for detecting the pressure in the storage tank. When the tank pressure reaches the set value, the high-pressure switch automatically cuts off the pump’s operating signal, preventing overpressure operation. This not only protects the pump and membrane module but also ensures more stable water output. Many issues where “the pump keeps running” are often related to a faulty high-pressure switch or abnormal wiring.

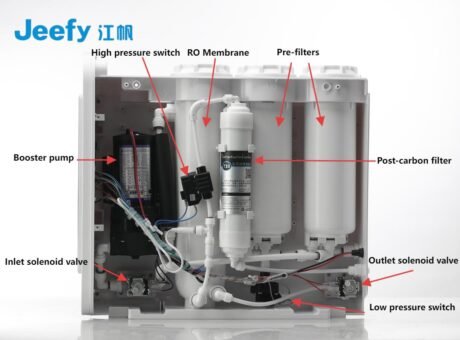

Internal Structure

- Pressure Tank & Post-carbon Filter

Water flows from the reverse osmosis (RO) membrane through a check valve into the pressure tank. When dispensed, it passes through the post-carbon filter for final polishing.

- Outlet Solenoid Valve (Dispensing valve)

At the outlet side, there is usually an outlet solenoid valve or a control mechanism linked to the faucet, ensuring that water is released only when needed, preventing backflow, and making it easier for the program to distinguish between flushing, water production, and refilling states.

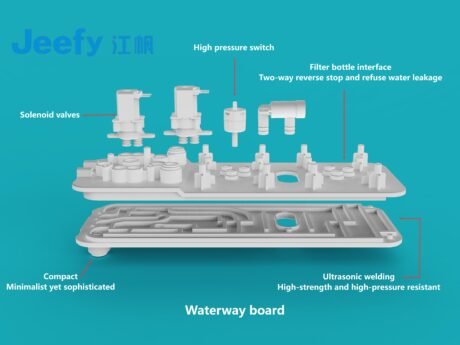

- Integrated waterway board

It is worth mentioning that some high-end models now adopt an ultrasonic-welded integrated waterway board design (such as Jeefy’s M Series products). This structure integrates multiple water paths and valves into a compact module, reducing the large number of joints and pipes in traditional systems. It not only lowers the risk of leaks but also makes the internal layout tidier. Our company’s flagship M series adopts this technology, achieving superior leak protection and easier maintenance.

RO Water Board

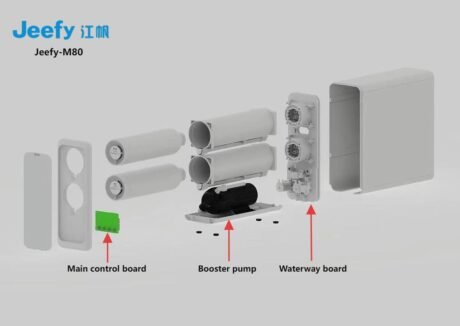

- Main Control Board

The main control PCB monitors sensors (TDS, pressure, leaks) and controls pumps and valves. It can also integrate Wi-Fi modules for remote monitoring and other features. For example, Jeefy’s B2 commercial unit‘s control board features a TDS reading, pressure reading, leak detection, and unit status display.

Exploded View of an Reverse Osmosis System with Water Board and smart control board

How an RO Water Purifier Works: Step-by-Step

- The controller checks if water pressure is adequate.

- If not, the booster pump kicks in and the inlet valve opens.

- Water flows through filters, gets pushed through the RO membrane, and is split into pure water and waste. Sensors decide if a quick flush is needed.

- If you have a tank, the controller checks if it’s full; if so, it stops the pump and closes the valves.

That “click” sound? It’s usually a valve opening or closing. The “hum” you hear? The pump at work. Even the indicator lights flashing are signals from the brain inside. Once you understand these details, you will no longer be confused when you encounter a faulty sound.

Why Understanding RO Components Matters?

Smarter Choices: Two purifiers might look the same on the outside but have completely different internal designs that affect performance.

Easier Maintenance: You’ll know if a problem is due to water pressure, a clogged filter, or a worn-out pump.

Faster After-Sales Support: You can describe problems like “the pump keeps running but no water flows,” helping technicians diagnose issues faster.

Confidence & Transparency: Understanding the machine builds trust — you know exactly what you’re buying.

By learning the function of each reverse osmosis water purifier component, you gain a better grasp of the full system.

Interested in custom water purification solutions?

As a water purifier manufacturer specializing in OEM & ODM services, we offer a range of customizable solutions tailored to your business needs. With over 15 years of industry commitment, our team of 100+ experts drives excellence across every stage of production. Backed by a daily capacity of over 2,000 units and 40+ quality test stations, we operate within an expansive 20,000-square-meter facility, ensuring superior quality and reliable performance in every product. Learn more about industry standards in water treatment at WQA – Water Quality Association.

Get in touch

Email: info@jeefywater.com

WhatsApp / Mobile: +86 15639766855

What’s next?

Stay tuned! In the next blog of Jeefy’s Water Purifier Classroom, we’ll take these valves apart, show their structure, explain how they work, and how to choose and troubleshoot them.